The good thing is you only need to do this on one end. Unfortunately the case gets chipped easily when taking it apart. A couple of the other trims are a bit off, but I think I can get to them at least. I'm not sure how much I will need to trim, but that would make it very hard to do. it's off and well, it turns out the holes on the cover may be a bit off, but the last one was really off on my g540. The reason I openened it was to find out what version it was and also to see if the trim pot on the edge could be moved to match the hole.

#Gecko g540 resistor pro#

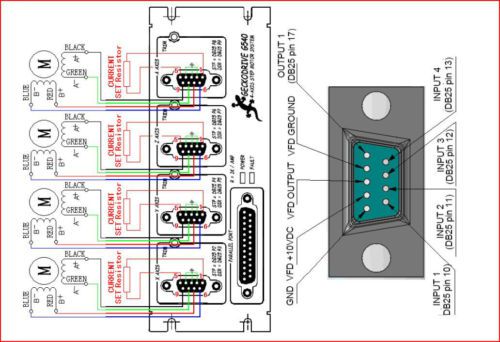

Pro Shielded Motor Cables (Made With Signal Cable) - YouTube. I also include the matching resistors for the G540.

#Gecko g540 resistor driver#

I think a screw on case may work too and keep you from making your brand new G540 look old after you open it. This system is built around the Gecko Drive G540 digital integrated micro stepping 4 axes driver system. The reason I guess was designed this way, or at least one of the reasons is that the case is used as a heat sink. It's hard as heck so I ended up bending the tab a bit and it shows unfortunately. This is one of the toughest cases I have had to open. Do this on the opposite side and pull the middle cover out as you do this.

I found this to be the best way to do this. To open the case, put a small flat screw driver from the side of the tab and push up. Gecko G540 (There are many resellers out there, the current version as of this writing is 8). Mini Mill Item # 44991 found on this page (This one is from harborfreight, but a few others are available). I'll try to keep them in an order that will be easy to follow. I will be adding items and or pages as they come up. So I hope this will be of some interest or just a nice read for anyone. I try, but it's what I know I like to do and I know I'm pretty good at this, and this is one of the reasons I'm starting a new site here on google. I'm just a novice so I still have a lot to learn myself, but I like to document things in an easy to follow manner so others can understand. This is also my first cnc item so I have a long way to go, but just want to make sure that others have a good idea as to what this is and does in case they are interested in cnc machining as well. I want to document this process as much as possible as it's not something you do overnight. I've had this mill for a few years now, but my intentions was always to convert to cnc. Basically I want to eventually convert my harborfreight mini mill to cnc. There are many reasons as to why but I'll stick to the subject. This past Friday my Gecko G540 finally came in.

0 kommentar(er)

0 kommentar(er)